Major Bi-Fuel System Components and Sub-Systems

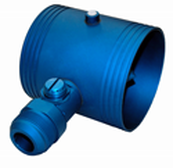

AIR-FUEL MIXER

The air-fuel mixer of the patented GTI Bi-Fuel System, located downstream of the gas power valve, incorporates a fixed venturi design.This innovative mixer is installed such that all of the incoming air flows through the mixer. For engines with multiple air intake systems,one mixer is at each of the intakes. The GTI Bi-Fuel System uses mixing devices that do not incorporate any type of air throttle plate in their design. After exiting the mixing device, the air-gas mixture enters the engine air-intake manifold, and distributes the charge to each cylinder via the normal air distribution scheme of the engine.

GAS POWER VALVE

The gas power valve, located downstream of the gas pressure regulator, is a needle-type valve and is one of the adjustable components to the GTI Bi-Fuel System. This device is set during the tune-in phase of the engine conversion and sets the maximum gas flow rate to the engine.Once set, this valve remains in a fixed position regardless of engine load.

Note: For added flexibility on engines that operate over a wide spectrum of load levels, an optional, automatically actuated gas trim valve is substituted for the gas power valve.

Note: For added flexibility on engines that operate over a wide spectrum of load levels, an optional, automatically actuated gas trim valve is substituted for the gas power valve.

GAS TRAIN

Conditioning and regulating the natural gas prior to admission into the engine is a critical part of the GTI Bi-Fuel System system. The system “gas train ” includes a 20-micron fuel filter, a manual shutoff valve, an electrically operated solenoid valve actuated in the event of an emergency or for system shutdown, and a zero-pressure, demand-type gas pressure regulator. This latter component reduces the inlet gas pressure (1–5 psi) to roughly atmospheric pressure. With a negative outlet pressure, the design allows the system to use a “demand ” control scheme whereby engine intake airflow determines the gas flow of the engine. As engine load changes, corresponding changes in intake air volume automatically draw additional fuel into the mixer.

Manuals and data sheets for gas train components are available at the DUNGS web site: http://www.dungs.com/en/index.html.

Manuals and data sheets for gas train components are available at the DUNGS web site: http://www.dungs.com/en/index.html.

CONTROL PANEL

The Control Panels are based on proven Altronic controllers and provide state-of-the-art engine control and safety shutdown monitoring. The system is designed specifically for GTI Bi-Fuel applications and is straight-forward and easy to operate. The panel monitors a number of pressure and temperature points and returns the engine to 100% diesel operation should any parameter deviate from its normal range. In addition, an hourmeter function tracks the operating hours when in Bi-Fuel mode.

Alarms are annunciated in English-language messages (other languages can be programmed), and the controller maintains an alarm log of the last 100 events.

Alarms are annunciated in English-language messages (other languages can be programmed), and the controller maintains an alarm log of the last 100 events.